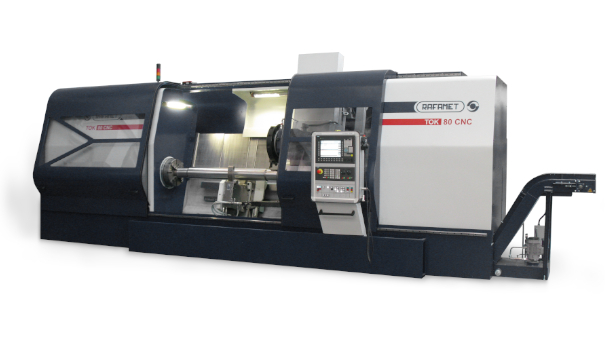

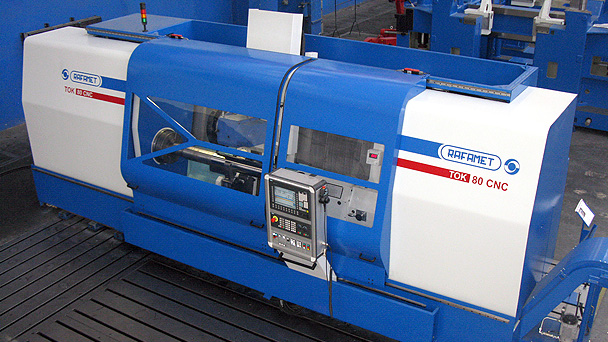

BASIC TECHNICAL SPECIFICATIONS

| Swing over bed: | 800 mm |

| Maximum weight of workpiece: | 6,000 kg |

PURPOSE

The TOK 80 CNC is a special-purpose horizontal lathe designed for turning of Railway wheelset axles.

The application of the latest CNC system allows for automatic, precise and productive workpiece machining according to technological program.

The machine tool enables to perform both rough and finish machining of worn and new axles.

The TOK 80 CNC Axle Lathe is capable of the following operations:

- Tuning of outboard and inboard journals

- Turning of axle body, wheel seats and dust-shield collars

- Turning of radii, roundings and chamfering

- Burnishing of outboard and inboard journals, axle body, radii, wheel seats and dust-shield collars

- Axle facing and centering

- Drilling and tapping of axle faces

MAIN FEATURES

- Slant bed made of high-grade cast iron of enhanced mechanical properties, standardized, heavily ribbed with four guideways made as hardened and ground steel blocks

- Carriage travel along two guideways ensuring its precise guidance

- Longitudinal and cross-wise travels along guideways lined with anti-friction material and assisted by central lubrication system

- 8-position turret

- Headstock body made of high-grade cast iron of enhanced mechanical properties

- Spindle rested on bearings of increased accuracy class

- All shafts and gears carburized, hardened and ground

Other products from this category

ABOVEFLOOR WHEEL LATHES

UNDERFLOOR WHEEL LATHE

MEASURING SYSTEMS

DIAGNOSTIC SYSTEMS

SHUNTING EQUIPMENT

WHEEL BORING MACHINE