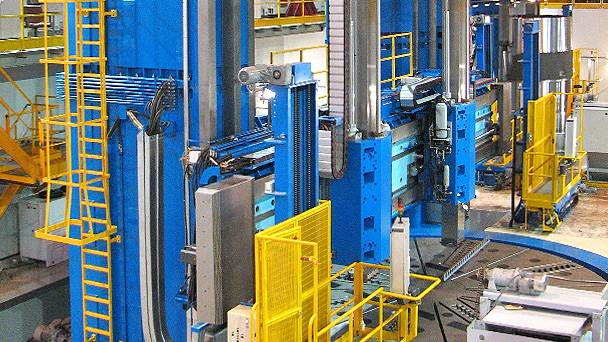

Double column lathes / workpiece up to 350 tonnes

BASIC TECHNICAL SPECIFICATIONS

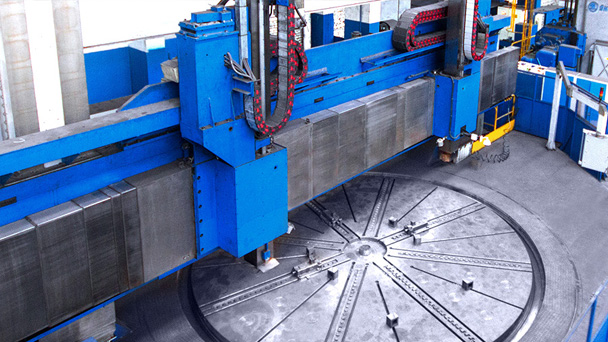

| Maximum turning diameter: | 14,000 mm |

| Maximum height of workpiece: | 6,300 mm |

| Maximum table load: | 350 × 10 kN |

PURPOSE

The KDC Series Heavy-duty Double column Vertical Turning Lathes are intended for turning and boring of cylindrical, conic and curved surfaces, as well as complex shaped large-size workpieces.

The railhead can be equipped with a tool spindle, making it possible to perform also drilling and milling operations.

The use of the latest Siemens SINUMERIK ONE and digital drive technology guarantees maximum performance and the complete compatibility of all drive and control components.

The KDC Series Vertical Turning Lathes along with a wide array of optional equipment are customized to meet the Customer’s individual requirements.

The machine tool body system consists of base with table, two columns and connecting beam all mechanically connected what forms a rigid and stable frame structure. The machine tool major members as base, table, columns, cross-rail and railhead are made as high grade iron castings. This ensures both high geometrical stability and excellent vibration damping, better than those of the fabricated structures.

MAIN FEATURES

- Compact design tailored to stringent machining requirements

- High rigidity and accuracies of machining

- Complex machining of workpieces with one or two railheads

- Railhead(s) for turning, optionally for milling and drilling operations

- Feed drives of X and Z axes realized through precise ball-screw transmissions

- Tool / toolhead magazines - option

- Direct measurement of CNC axes position by means of Heidenhein high-resolution linear scales

- Twin main drive and C-axis drive

- Hydrostatic guideways for railhead and ram travel - option

- Available with table travel drive (Y axis)

- ISO/BT, CAPTO, KM or any other tooling system

- Measurement of cutting tools - option

- Measurement of machining workpiece - option

- Grinding attachement - option

- Cooling system for cutting tools - option Max. working pressure: up to 350 Bar