Wheel boring and machining

BASIC TECHNICAL SPECIFICATIONS

| Maximum turning diameter: | 2,000 mm |

| Maximum weight of workpiece: | 2 × 10 kN |

PURPOSE

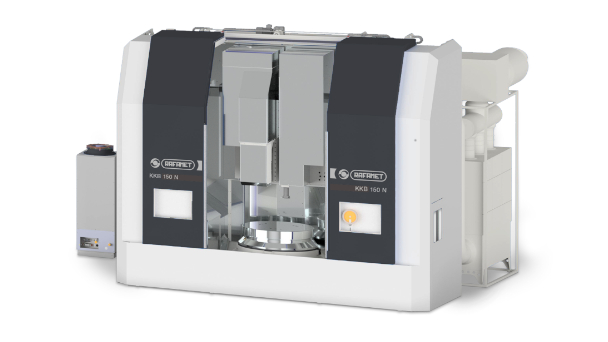

The KKB 150 N Vertical Turning Lathe is single-column Wheel Boring Machine specifically designed for productive machining of railway wheels with two railheads.

The machine tool can perform the following turning operations controlled by technological program:

- Wheel hub fine boring;

- Hub facing;

- Chamfering;

- Wheel hub rough boring with 1-mm allowance on each side.

With a special equipment, it is possible to extend the machine capabilities to the following operations:

- Machining of solid wheels;

- Machining of wheel centres;

- Boring of tyres;

- Drilling of assist oil injection holes in wheel hubs.

For wheel production purposes a double railhead version of increased productivity can be provided.

MAIN FEATURES

- Machine column and cross-rail combined into a single-piece (monolithic stucture);

- Major body components made as extremely rigid, heavily ribbed box-type, high-grade grey iron castings providing maximum vibration damping capabilities during cutting process;

- Main drive powered by modular torque motor with continuously variable speed control;

- Workpiece measuring probe (of Renishaw or equivalent make) mounted in tool seat;

- Solid forged steel railhead ram equipped with a Coromant CAPTO® quick change tool adapter and HSK® angle machining head;

- Tool / toolhead magazines.

Other products from this category

ABOVEFLOOR WHEEL LATHES

UNDERFLOOR WHEEL LATHE

IT SYSTEMS

MEASURING SYSTEMS

DIAGNOSTIC SYSTEMS

SHUNTING EQUIPMENT

WHEEL BORING MACHINE