BASIC TECHNICAL SPECIFICATIONS

| Max. work space of frame: | 4,000 × 1,670 mm |

| Max. power of spindle motor | 22 kW |

| Max. spindle rotation rate | 24,000 rpm |

| Max. ram travel | 1,400 mm |

PURPOSE

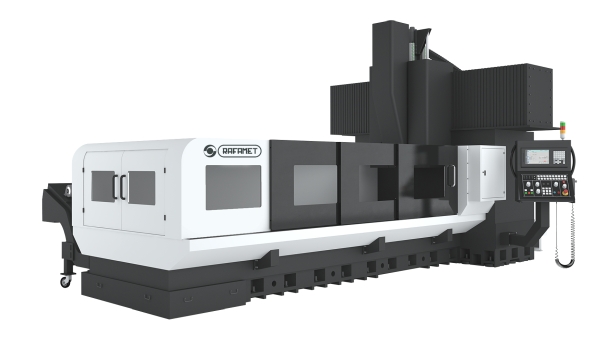

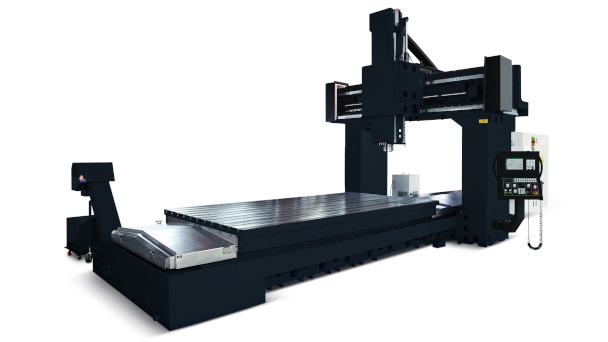

The FBC Series Milling Machines are the CNC Planer Mills designed for machining of the complex workpieces.

The FBC Series Milling Machines are capable of the following:

- 3D milling;

- Drilling;

- Reaming;

- Boring;

- Threading, envelope threading (helical motion) in all machining planes, i.e. XY, YZ, XZ

The FBC Series Milling Machines allow to machining of large-size models with weight up to 30 tonnes. Rigid cast iron body system is resistant to vibrations. In combination with CNC numeric system, these machine tools are characterized by high precision and accuracy of workpiece machining. The milling machines allow loading and unloading from the top, side and front of the machine - allow to choose the loading and unloading method best suited to the type of workpiece.

MAIN FEATURES

- Fixed frame of machine tool with fixed cross-rail;

- Movable table;

- Spindle termal stabilization;

- Z-axis hydraulic counter-balanced;

- 5-sided machining;

- 2-arm tool changer;

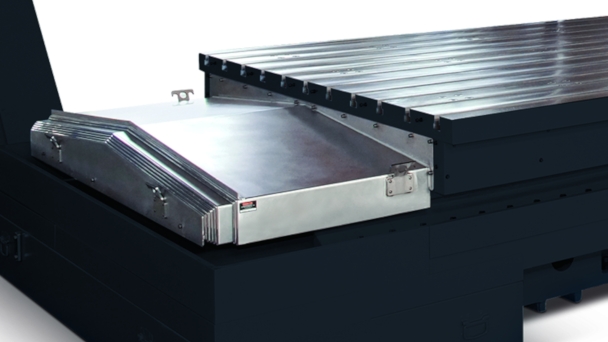

- Fully enclosed splash guards;

- All movable assembly units travel along precise rolling guideways