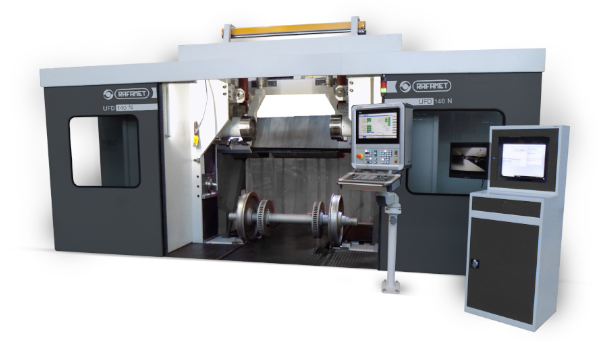

Roll-through Wheel Lathe for wheelsets machining / Friction drive

BASIC TECHNICAL SPECIFICATIONS

| Range of wheel tread diameters: | 540 to 1,400 mm |

| Maximum wheelset weight: | 5 × 10 kN |

PURPOSE

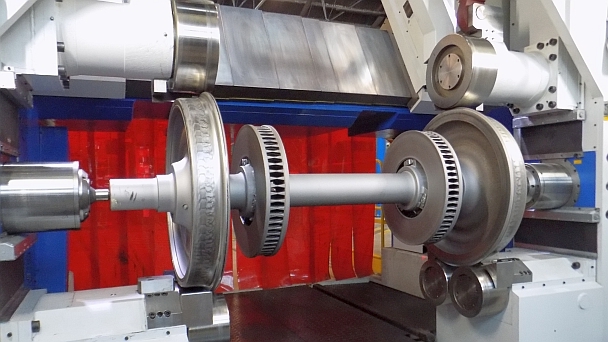

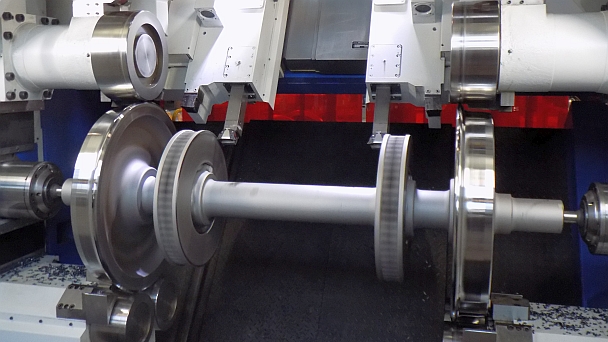

The UFD 140 N Portal Wheel Lathe is a CNC double-saddle special-purpose lathe designed for reprofiling of wheels and brake discs used in rail vehicles. Thanks to optimised design features and high power of main drive the machine tool ensures productive machining of solid (monoblock) wheels and wheels with tyres of both used and new wheelsets. The friction roller drive allows to avoid notches on wheel surface which may expand to the fatigue damages of the wheels.

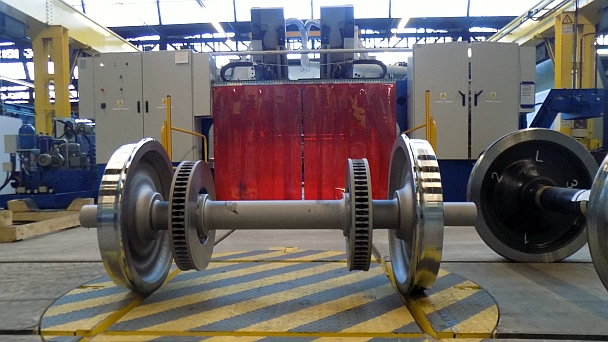

The wheelsets can be provided with outboard axle boxes, gears installed between the wheels and brake discs.

The wheelset is rolled onto the built-in wheelset elevator along rails, automatically centred and clamped between the centres and the friction drive rollers - three rollers are attached to each wheel.

The machine tool main structure is made in the form of a portal enabling wheelsets unloading to its rear side in roll-through flow. It is also possible to unload the wheelsets to the machine front side.

The main drive is powered by four AC motors of infinitely variable rotation rates and digitally controlled in master / slave system.

The UFD 140 N Portal Wheel Lathe is capable of performing the following operations:

- Turning of wheel profile according to technological program;

- Wheel rim inner facing;

- Wheel rim outer facing;

- Turning of limit machining groove;

- Turning of tyre in order to remove retaining ring;

- Turning of wheel centre;

- Axle-mounted brake discs facing;

- Wheel-mounted brake discs facing.

MAIN FEATURES

- Major body elements made as extremely rigid, heavily ribbed box-type high-grade iron castings in the form of portal guaranteeing the best dumping of vibrations produced during cutting process and excellent chip evacuation;

- Main drive from four friction rollers individually powered by AC motors of infinitely variable rotation rates and digitally controlled in master / slave system;

- Automatic and reliable profile wear measurement using touch-type measuring heads;

- Productive machining of narrowed (economical) wheel profiles;

- Versatile equipment and wide programming capabilities facilitate easy machining of unusual wheel profiles;

- Operation in roll-through or roll-in roll-out system.

Other products from this category

ABOVEFLOOR WHEEL LATHES (4)

IT SYSTEMS (4)

DIAGNOSTIC SYSTEMS (4)

WHEEL BORING MACHINE (4)

AXLE LATHE (4)

MILLING MACHINE FOR BOGIE FRAMES (4)

EQUIPMENT FOR TECHNOLOGICAL LINES (4)