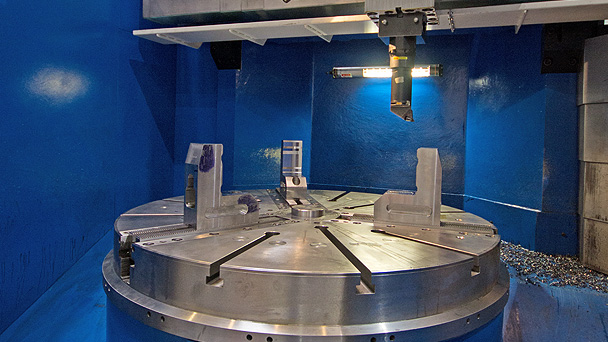

Wheel boring and machining

BASIC TECHNICAL SPECIFICATIONS

| Maximum turning diameter: | 1,800 mm |

| Maximum weight of workpiece: | 6 × 10 kN |

PURPOSE

The KCM 150 N single-column wheel boring machine is designed for machining of railway wheels.

The machine tool can perform the following turning operations controlled by technological program:

- Wheel hub fine boring;

- Hub facing;

- Chamfering.

With a special equipment, it is possible to extend the machine capabilities to the following operations:

- Wheel hub rough boring with 1-mm allowance on each side;

- Machining of solid wheels;

- Machining of wheel centres;

- Boring of tyres;

- Drilling of assist oil injection holes in wheel hubs.

For wheel production purposes a double railhead version of increased productivity can be provided.

MAIN FEATURES

- Major body components made as rigid, heavily ribbed, box-type high-grade iron castings providing high geometrical stability and efficient vibration damping;

- Main drive powered by AC motor of infinitely variable rotation rates;

- Solid forged steel railhead ram equipped with a Coromant CAPTO® quick change tool adapter;

- Workpiece measuring probe (of Renishaw or equivalent make) mounted in tool seat.

Other products from this category

ABOVEFLOOR WHEEL LATHES

UNDERFLOOR WHEEL LATHE

IT SYSTEMS

MEASURING SYSTEMS

DIAGNOSTIC SYSTEMS

SHUNTING EQUIPMENT

WHEEL BORING MACHINE

AXLE LATHE

MILLING MACHINE FOR BOGIE FRAMES

EQUIPMENT FOR TECHNOLOGICAL LINES